After 2018’s Red Hat triumph, we laid off for a year to see how our feelings vis-a-vis Bonneville racing developed. Would we be sated by that odyssey? Would we be anxious to return? Would the team take up iron-butt motorcycling instead?

Turns out that Salt Fever is not so easily cured. The team chatter about ‘trying to raise the Blown Gas Coupe record‘ started near the end of 2019. Here’s what we were thinking: this car ran 200+ on its last four outings, and nothing the motor said or did suggested that it’d been hurt by those record passes; if we just changed out some bodywork, Pickle would fit into another class, with a record just over 175mph. Shouldn’t it be easy to crank that up?Isn’t its mere existence at that level, in fact, a demand that it be raised?

In early 2020, a critical mass of interest formed, and work started. Pickle’d been resting in the Car Palace since it was cleaned up on our return in 2018, but now it was pulled out of hibernation and went on the lift. There was a bit of corrosion on the underbelly… then we found the frozen brake calipers… then found the immobile suspension… then noticed the funny way the turbo spun. Hmm. It doesn’t like sitting around, does it?

Another major challenge was that the engine control unit (ECU) and its complete harness had been removed. These components had been lent to Pickle for the 2018 meet, and were returned to the owners after. We got a duplicate ECU and harness, but figuring out where all the connectors and power leads went consumed several days. And one ECU output, for the tachometer, stubbornly refused to talk to the dash-mounted instrument, or at least it didn’t move the needle. We thought we’d keep trying when we had time…

Boom! It was August, and Speed Week was here. We packed a bunch of tools and the whole team, and went to the salt.

Car #8600, the Flying Pickle, arrived Saturday morning and we set up pits east of Tech Inspection. Covid has changed the workflow on the salt, and the TechInspector (1) now comes to your pit as opposed to the car going to Tech Inspection. Formerly, there were three or four inspectors focused on each car as it came through, but now (having to account for travel out to various pits), there’s only one inspector.

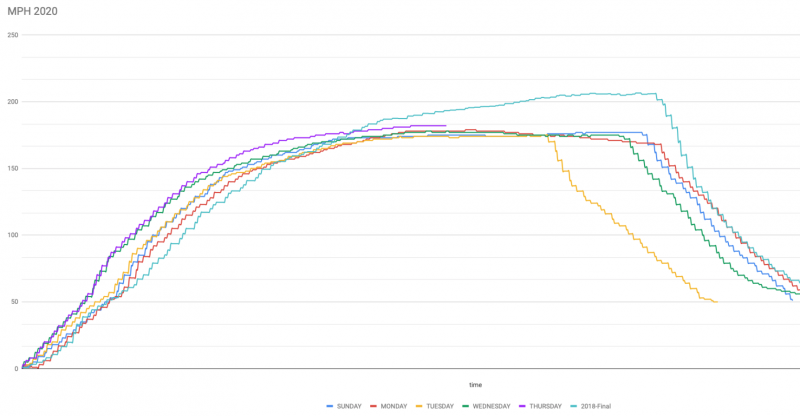

We made a run on Saturday afternoon, but it was quite slow – around 165mph. That was a bit puzzling because this same motor/car combination ran over 200mph on its last outing. We turned to our old friend, ‘data’, to look for clues for the slowness… but found that both data collection systems had had problems on that Saturday run. The cause of those faults? Corrosion in electrical connectors. What they did tell us was that the driver was shifting early, and he admitted as much: “Without a tach, it is really hard to tell how high you’re spinning it. You have to realize how violent the experience is when the motor hits its sweet spot.” Hmmm… guess we better make the tach work.

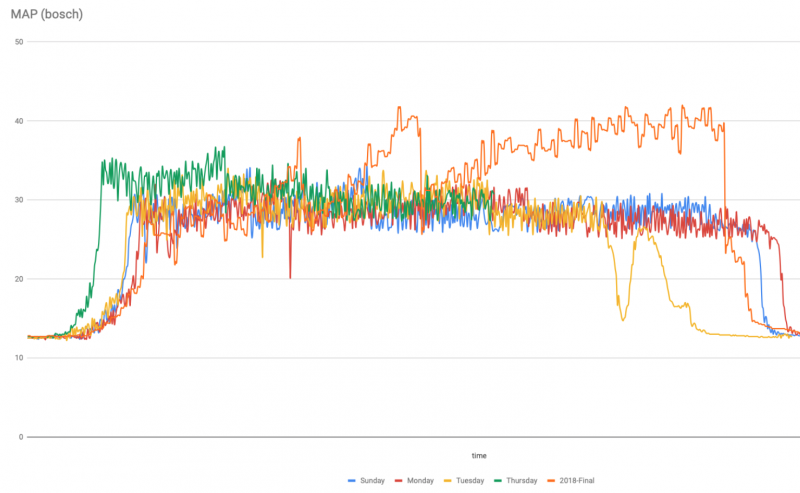

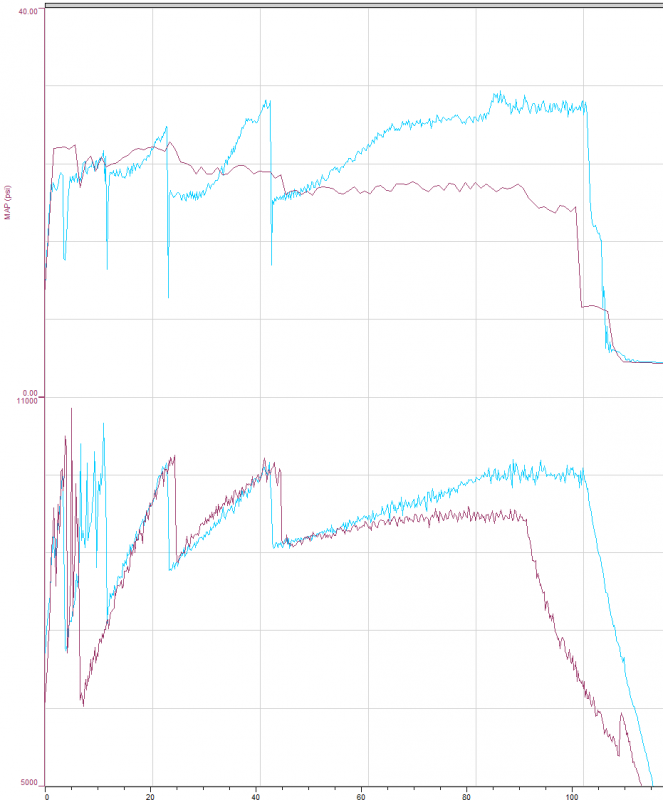

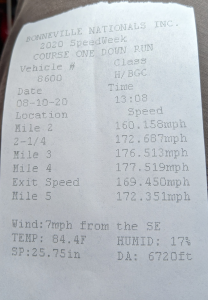

Sunday we’d corrected the tach issue, and fixed the data collection problems, but we still weren’t reaching speeds we expected. Pickle went around 177mph. The data said that turbo boost fell off after the shift to fifth gear, and the car barely gained speed thereafter. It looked to us like the rpms in fifth gear were just slightly below the level where the turbocharger ‘takes over’, pushing more and more air into the engine and then feeding off the exhaust from that bigger meal. Turbochargers are self-reinforcing in that way, and require pressure relief valves in the exhaust plumbing to reduce the feedback effect. Otherwise the cycle continues ‘until a mechanical limit is reached’.

Sunday’s speed was still enough to qualify for a record attempt (barely), so the car went to the impound area for a designated work period and a ‘record run’ the following morning. While we were prepping systems in Impound, though, a gaggle of Tech Inspectors came over and told us the roof rails on the car were out of specification, and disqualified our run. I suspect that the issue would have been caught had the normal Tech Inspection routine been in place.

We towed Pickle out of impound, and removed the errant roof rails in our pits. Monday morning we made a small adjustment to the fueling in the rpm band corresponding to the rpm after a gear shift, and had the driver hold fourth gear to 10,200 rpm — hoping to land high enough in fifth gear to let the turbo pull it up into the powerband.

Our speed of 176mph again qualified us for a record attempt the next morning, so we were back in impound Monday afternoon, racking our brains to figure out why we weren’t going faster. We’d also noticed that Pickle was becoming very hard to start. It would crank without firing, pop a little, then crank again. We tried various combinations of throttle opening, fuel pump on/off, … crossing our fingers … but the hard starting coupled with the lack of speed had us doubting our assumptions.

Tuesday we were at the end of the road at 6am, along with other teams whose vehicles would be making record attempts. The officials led us out to the Impound area for a brief work period, and TeamPickle had a little extra time before we had to go to the starting line. We thought we’d start the engine to warm it up (and to reduce our anxiety about it not starting at all).

Our working theory Tuesday morning was that ‘cranking speed’ (the crankshaft rotational speed that the starter motor imparts) was low, and that was the cause of the hard starting. Pickle carries a large 12V battery on-board for running pumps, and this is also used for the starter motor. To augment that, we clamped on a battery charger, and connected our push truck’s umbilical cord. We had amps and volts a’plenty.

Press the button! whirr whirr whirr pop whirr whirr whirr whirr pop whirr whirr whirr whirr… (repeats)

Now our anxiety was back twofold. What is causing this?! The deadline to leave Impound was imminent. With nothing to lose, we decided to try bump-starting Pickle during the tow to the starting line. Hey – it works on motorcycles… sometimes.

And it worked for us: the engine fired very quickly, and we let it run during the tow to the start line. (We noticed on Thursday a.m. that other teams do similar bump starts… but I’m getting ahead of myself.)

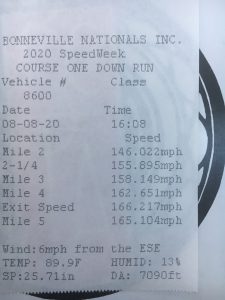

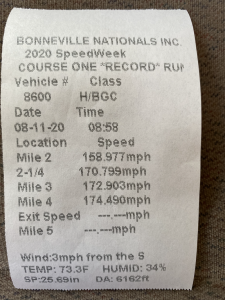

The record we were chasing was 176.393 m.p.h. Our speed on the qualifying run would be averaged with our speed on the ‘record’ run. Our qualifying speed was over the record by just a little bit, so we could set a new record if Pickle could manage 175.267 m.p.h. plus. Pah – this car can go over 200 m.p.h. Should be easy.

We didn’t make it. The top speed was 174-ish. We towed back to the pits, out of ideas and frustrated.

Luckily, we had fresh eyes in the pits, a visiting couple that we know from rally racing in the Pacific Northwest. Steve is a professional mechanic, and he was able to re-set our tangled brains into verifying the basics of internal combustion:

- compression

- fuel

- spark

The compression gauge came out, and we checked all four cylinders. They read:

90# – 30# – 30# – 50#

Well, there’s your problem, Bob. This engine normally has approximately 160# across the board. That could explain the hard starting. But it also seemed really low… with those kind of numbers, how (we asked ourselves) is the car going 175m.p.h.? We kind of shrugged and pointed at the enormous turbocharger. Perhaps with enough boost, static compression matters less? This was blowing our minds, but the facts where there, right in front of us.

We went looking for the cause of the low compression. A shot of oil into the cylinders (to help the piston rings seal) didn’t change the numbers. We thought it likely we’d burned the edges off the exhaust valves, and we were losing seal there. A check of valve clearances on the exhaust, though, showed all eight in spec. The mystery deepens. Almost on a whim, we checked the valve clearances on the intake side, and then checked them again; because seven of eight were showing zero clearance. That would cause the valves to be slightly open in their ‘resting position’, and that would certainly reduce compression.

Did we bring the shims needed to set the clearance on the intake valves? No-sir-ree, we had not. That is why, if you were on Interstate 80 between Bonneville and Salt Lake City on Tuesday lunchtime, you’d have seen me around max legal speed heading to an open motorcycle shop for a shim kit.

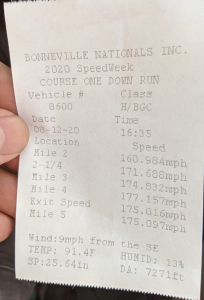

I won’t describe in detail the hours and hours of work it required to get clearance on those intake valves, but we next made a run on Wednesday, in the late afternoon. Result: 177 m.p.h., qualifying speed, and we were back in Impound for the third time.

None of us had then an explanation for why the intake valve clearance disappeared, nor have we come up with one since. But there were other strange things happening with and strange noises emitting from the engine, and together they’re like a big red flag waving: You’ve been asking me to put out 3x normal power for many runs now, and I am… getting… tired.

We figured our chances of succeeding in our record run Thursday morning were less than 50-50 (the greater odds were on the combination of ‘running too slow’ and ‘blowing up violently’.)

So naturally… we turned up the boost.

Well, the motor will need a complete rebuild anyway; at least we’ll have a chance at setting a record. This was our rationale. And, before now, we’d always been afraid to touch the boost knob, which was still at the setting chosen by the engine tuners. So we felt both compelled and naughty when we twisted it a full turn.

At the starting line the next morning, we were part of a Spectrum Of Speed; the other lane held a 60cc moped which hoped to make 48 mph. Then the Pickle, hoping for 190 mph. And next to us, the recent king of wheel driven land speed, the Speed Demon streamliner run by Poteet & Main, which was shooting for 480 m.p.h.

All three of us set records.

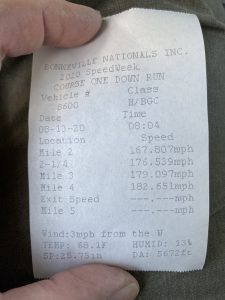

- The Pickle, just by the skin of its teeth. We ran 182mph with four pounds more boost than the day before. The average speed for our qualifying and record runs was a bit over 179mph.

- The moped made 50mph.

- The Speed Demon ran 480 and made it look very, very easy. Doesn’t take long to cover the five mile course when you’re over 300 at the two-mile mark. Our driver was outside the Pickle at Mile 6 when the streamliner driver(pilot?) pulled the ‘chute on the Speed Demon. Tom said he felt a shock wave in his chest.

We’d completely exhausted ourselves during the week, and managed to raise the record in 1500cc Blown Gas Coupe by a measly 3mph. But it is the current record.

See Run Data Here